Project Logs Page

Description of team progress done on a weekly basis.

3/30-4/05 and 5/11-5/17 images were sourced from websites. These websites can be accessed from selecting the specified image.

Description of team progress done on a weekly basis.

3/30-4/05 and 5/11-5/17 images were sourced from websites. These websites can be accessed from selecting the specified image.

Project scope and deliverables were reviewed with the mentor. Market research on CO₂ and methanol applications was conducted by Linh and Sophia to assess economic relevance. Research on CO₂ hydrogenation for methanol synthesis was also performed, leading to the selection of Cu/ZnO/Al₂O₃ as the catalyst due to its industrial use and strong literature support. A Python model using Jean-François et al. kinetics under ideal gas assumptions was developed, but results diverged from literature trends due to high-pressure operating conditions (10-60 bar) where ideal gas behavior is no longer valid. As a result, ASPEN HYSYS modeling was identified as necessary to account for non-ideal gas effects and ensure accuracy.

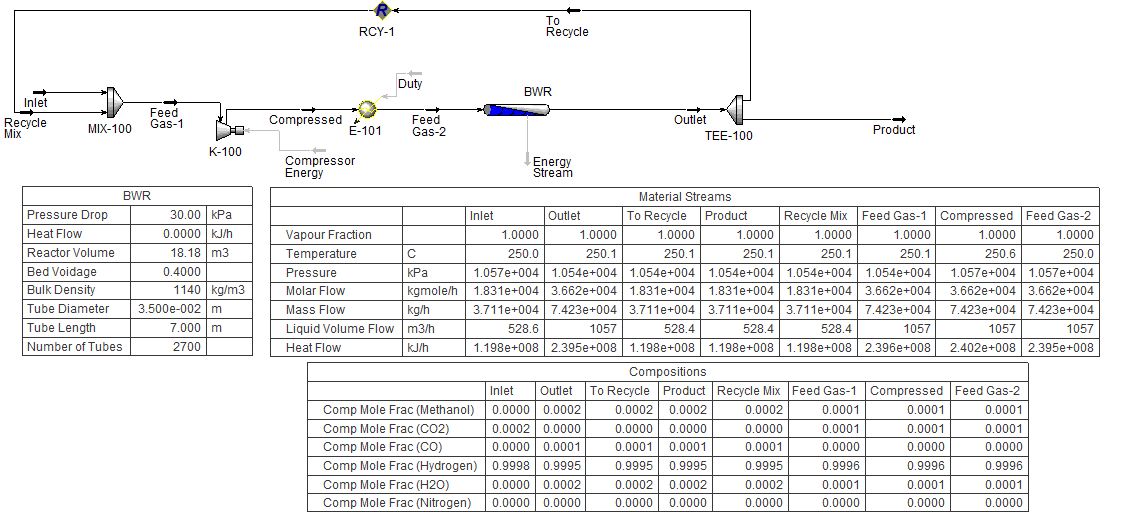

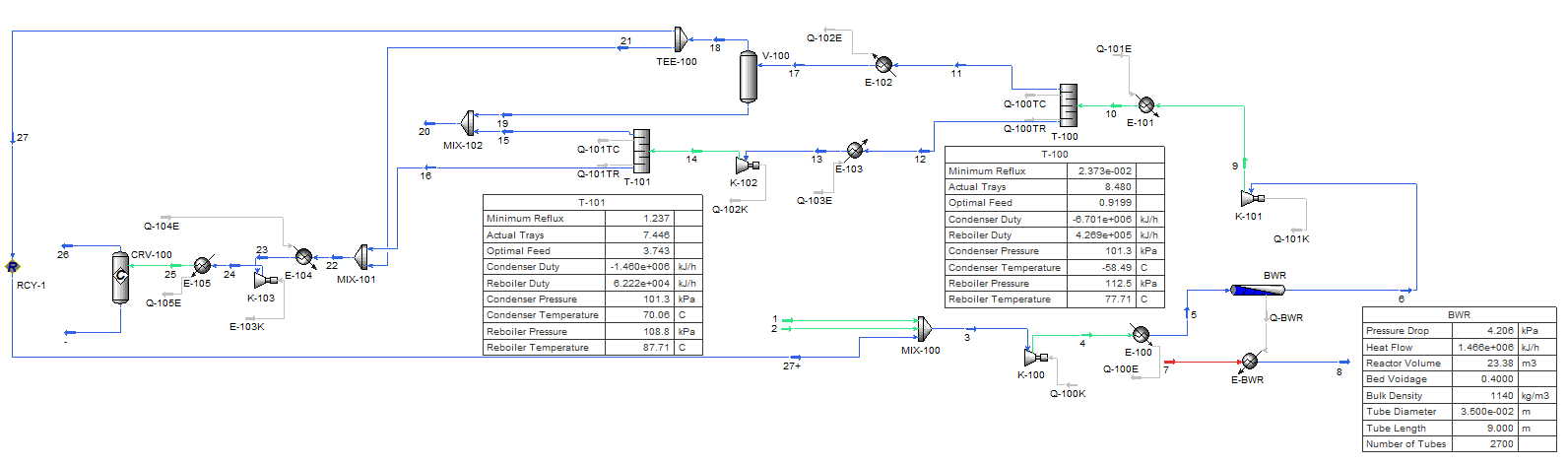

After extensive troubleshooting, a working ASPEN HYSYS model was developed using Van den Bussche and Froment kinetics from Jean-François et al., following the reactor configuration outlined by Shi, with the addition of a recycle stream to enhance methanol yield. Next steps include designing a downflow separation system to optimize the recycle loop. Proposal and update presentations were drafted and revised to reflect deliverables and current progress, and a project timeline was created in Notion.

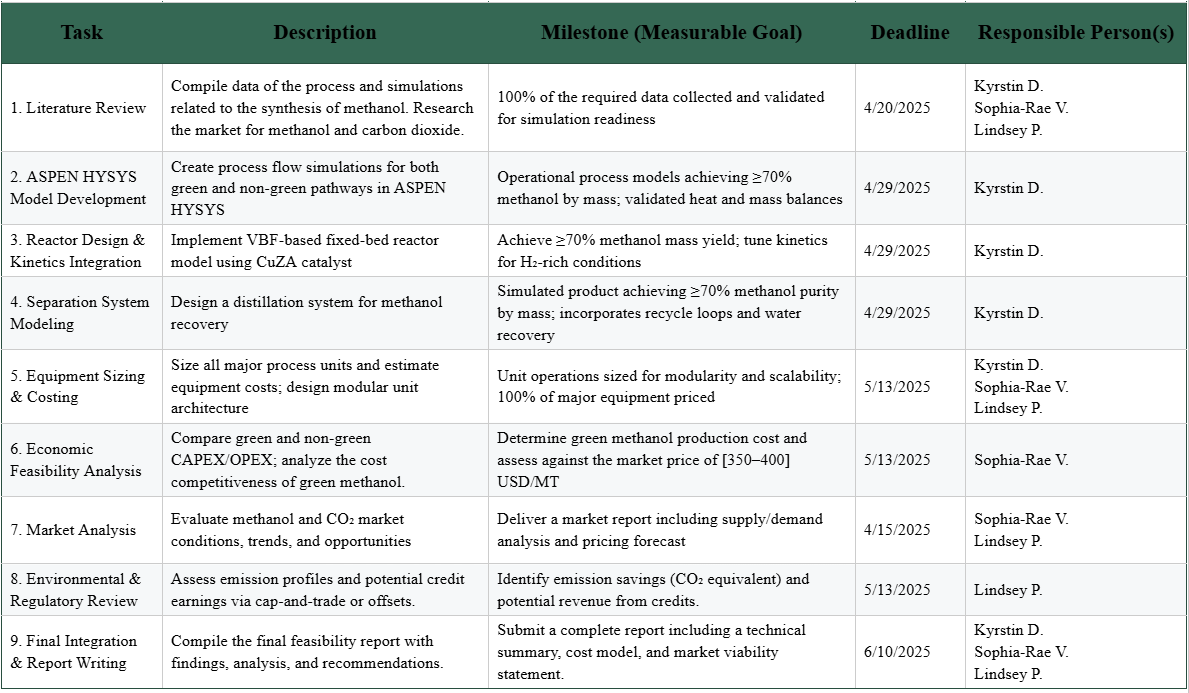

An update on project progress was presented to mentor, and project proposal was finalized to establish and confirm the direction of the methanol production pathway, which will involve a synthesis step followed by separation to achieve a 70 mass% crude methanol mixture, whereupon the treated feed will be sent to a central processing facility. Extensive and rigorous market research and expected pricing analyses were performed by Sophia and Linh to determine the economic and market feasibility of a green methanol process and to ascertain a target production cost necessary to ensure market competitiveness. Tentative deadlines were also proposed and determined by Sophia and Linh.

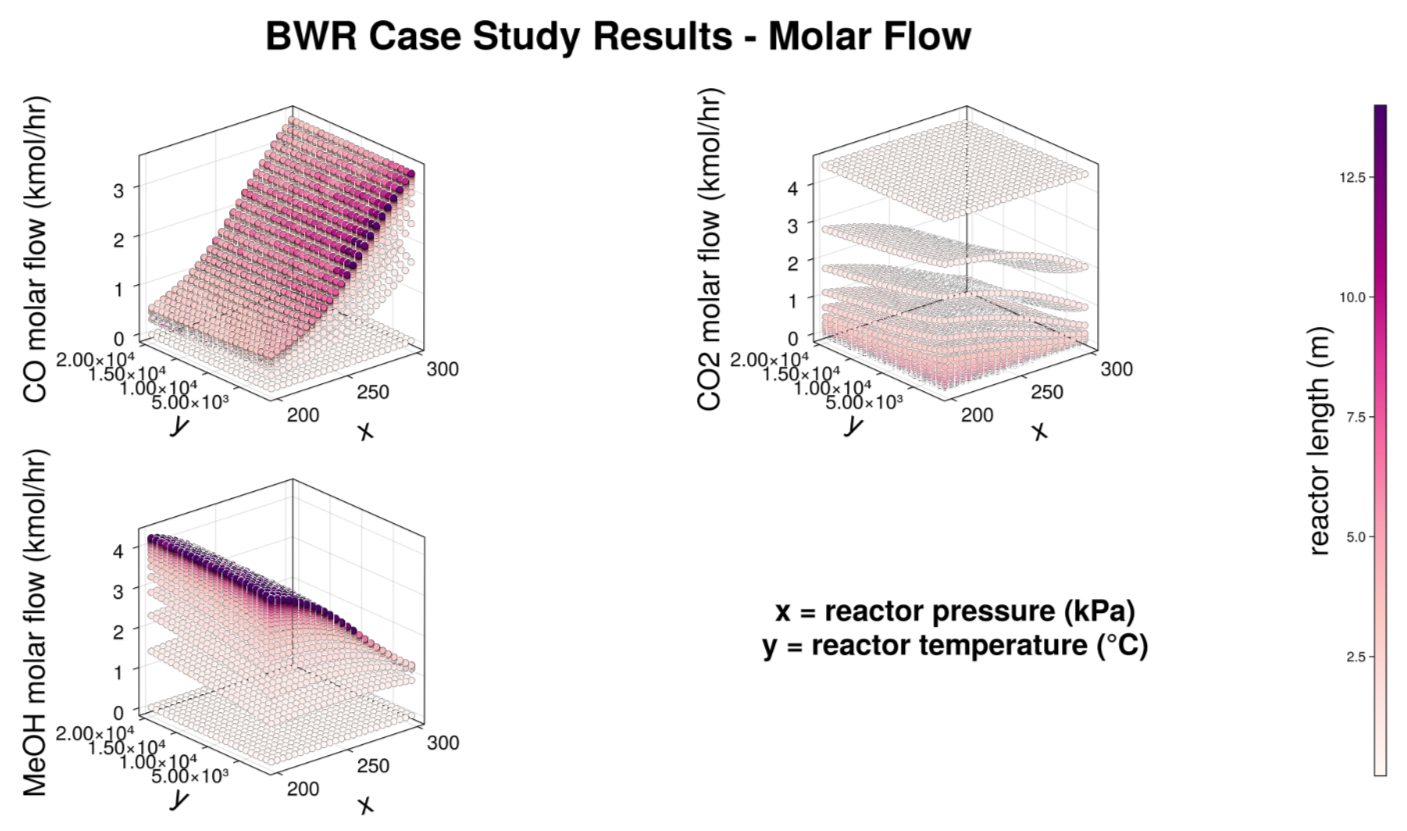

Case studies iterating through reactor operating conditions (temperature: 200–300 °C, pressure: 1 × 10³–2 × 10⁴ kPa) and reactor lengths (2–14 m), while monitoring outlet CO, CO₂, and MeOH molar flows and compositions, were performed to determine optimal reactor conditions. To meet modular specifications, a reactor length of 8.75 m operating at a temperature of 200 °C and a pressure of 2.00 × 10⁴ kPa was selected to achieve maximum MeOH selectivity (low CO content in the outlet flow) while maximizing CO₂ conversion. A separation system was developed using phase separation to remove H₂ gas from the mixture, followed by distillation to achieve a 99.5 mol% MeOH product, utilizing a distillation tower with 40 trays, a reboiler pressure of 120 kPa, and a condenser pressure of 101.3 kPa -- resulting in a pressure drop of .4675 kPa per tray. Prior to the update presentation, the distillation tower design must be further refined to deliver a separation system that meets modular specifications while purifying the reactor effluent to a 70 mass% methanol product.

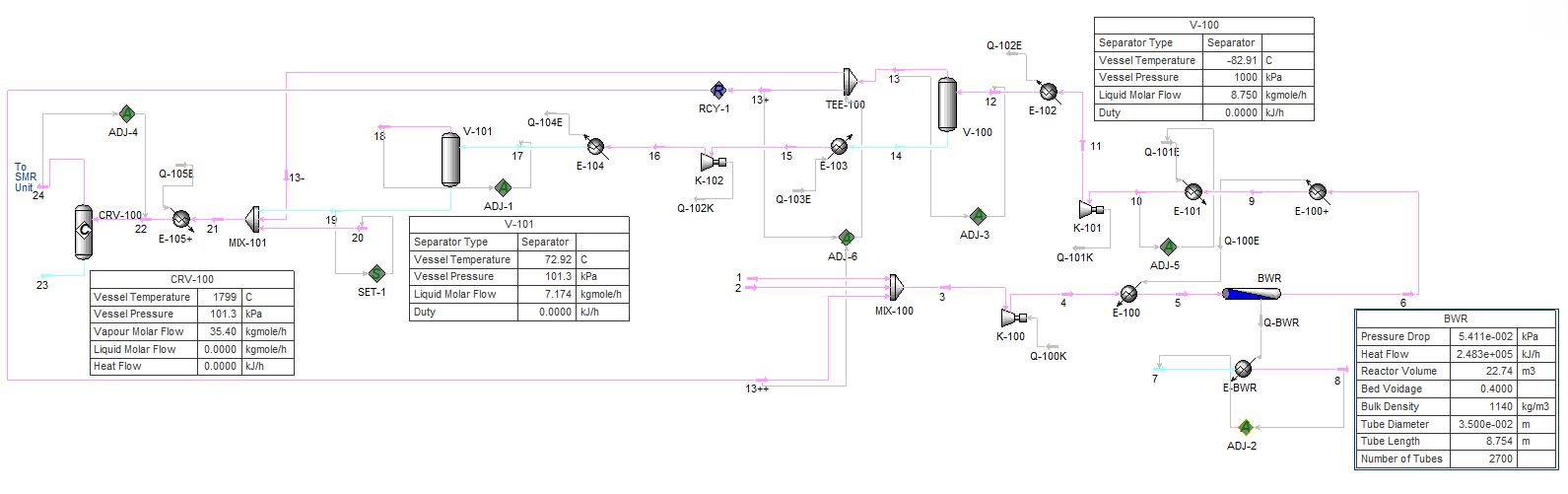

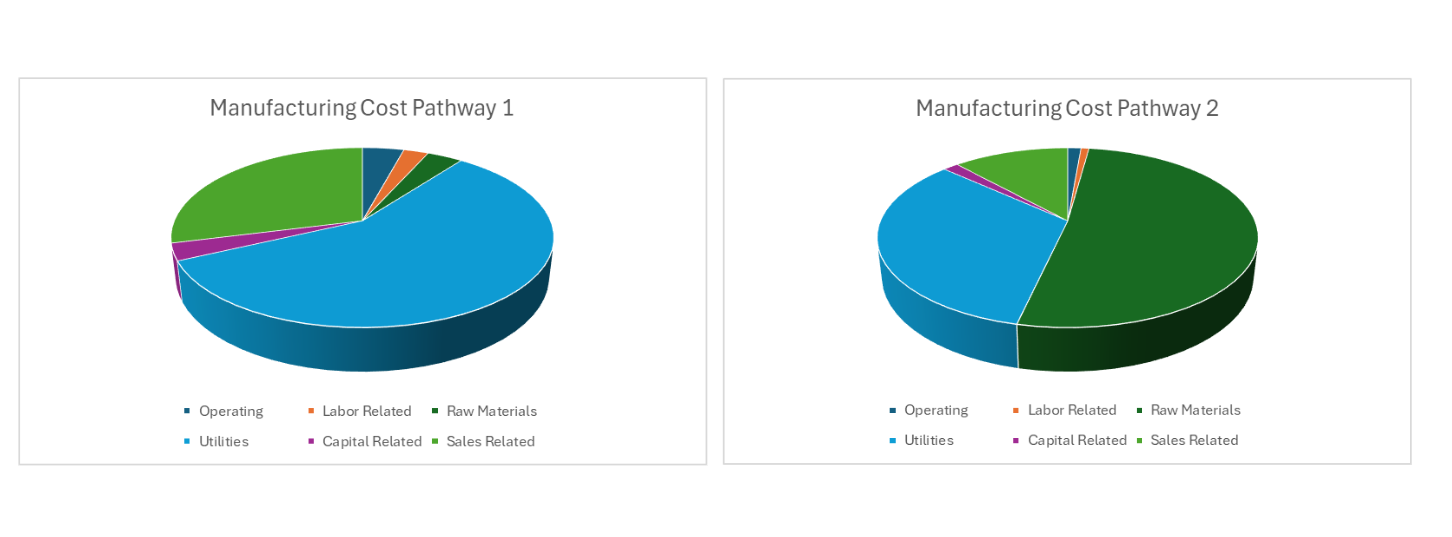

Linh and Sophia started on the equipment sizing and cost analysis of the current model in Excel. Methanol recovery system was switched from a distillation column to a phase separator with expander and heat exchangers tweaked to achieve the 70 mass% methanol specification in the tops vapor stream. The group decided to implement a combustion system that will to combust the residual MeOH in the bottoms liquid stream so that the produced vapor stream can be recycled back into HyGear's SMR unit for CO2 extraction. Vapor stream of the CO, H2, and CO2 extraction unit (V-100) did not converge with recycle (R) unit which was troublshooted by implementation of tee system, fractioning the stream for recycle and combustion. Future work requires sizing, pricing, and analysis of methanol production process to determine if this current model produces market competitive methanol, accounting for costs incurred by CO2 and H2 feedstock processes.

.png)

Based on feedback from a co-worker, a results section with an image slider was implemented to allow users to easily view all results alongside descriptive captions. Following a meeting with the mentor, several updates were made to the ASPEN HYSYS model: the reactor length was adjusted from 8.754 m to 9 m; the recycle separation system was changed from a separator to a distillation column to ensure complete recovery of H₂, CO₂, and CO in the top stream—excluding methanol; and the methanol product separator was replaced with a distillation column to minimize methanol loss. After receiving outlet H₂ and CO₂ conditions for both the conventional (SMR-based) and green methanol (biogas CO₂ and electrolytic H₂) pathways, these values were incorporated into ASPEN HYSYS, and two separate simulation files were created for the respective pathways. The website’s results section was updated accordingly. The College of Engineering Expo poster was finalized with these updates and submitted for printing. Linh and Sophia continued work on equipment sizing and cost analysis in Excel.

Time was invested into researching the green methanol market, while there has been significant research towards if international chemical and shipping sectors might be potential stakeholders in the green methanol market, there has not been much research towards the market specifically in the US or North America. Forecasts for production were found however were dependent on feedstock availability and cost rather than projected demand. ASPEN HYSYS models for conventional and green methanol production pathways were tweaked minorly to fix naming convention and required feed stream issues. Update presentation was worked on using the updated simulation models. Linh and Sophia continued working on the sizing and costing portions of the methanol process. Future work includes creating a non-modular version of the green methanol production pathway in order to perform a sensitivity analysis.

Linh completed the P&ID drafts for both conventional and green methanol pathways. Case studies were conducted on the green methanol pathway to determine the optimal electrolytic H₂ molar flow rate, with data visualized in Julia to support the selection. Distillation columns were adjusted accordingly, and a separator vessel was added to recover methanol from the recycle stream. A water-gas shift assembly was implemented in both pathways—replacing the combustion process—assuming complete conversion of carbon monoxide in the waste gas to carbon dioxide for safe emission. P&IDs were updated to reflect this change, and Linh and Sophia continued work on process sizing and costing.

Linh and Sophia completed process costing and sizing. A CAMEO Chemicals and Safety Datasheet (SDS) assessment was conducted to tabulate key flammability, health, and stability hazards for each process chemical, identifying dispersion, elevated temperature, and overpressurization risks. This informed the subsequent Hazards and Operability (HazOp) assessment of the reactor. A pressure relief valve system was designed based on HazOp findings. Material compatibility with process chemicals and conditions was also evaluated using ANSI/API standards as a guideline. The final presentation was then prepared.

Working on it! Will be updated on/after 06/07/2025.